Product Details

The large-angle belt conveyor has the advantages of simple structure, reliable operation and easy maintenance as the general belt conveyor. It also has the characteristics of large-angle conveying, compact structure, and small footprint. Therefore, it is an ideal equipment for large-angle conveying and vertical lifting of materials.

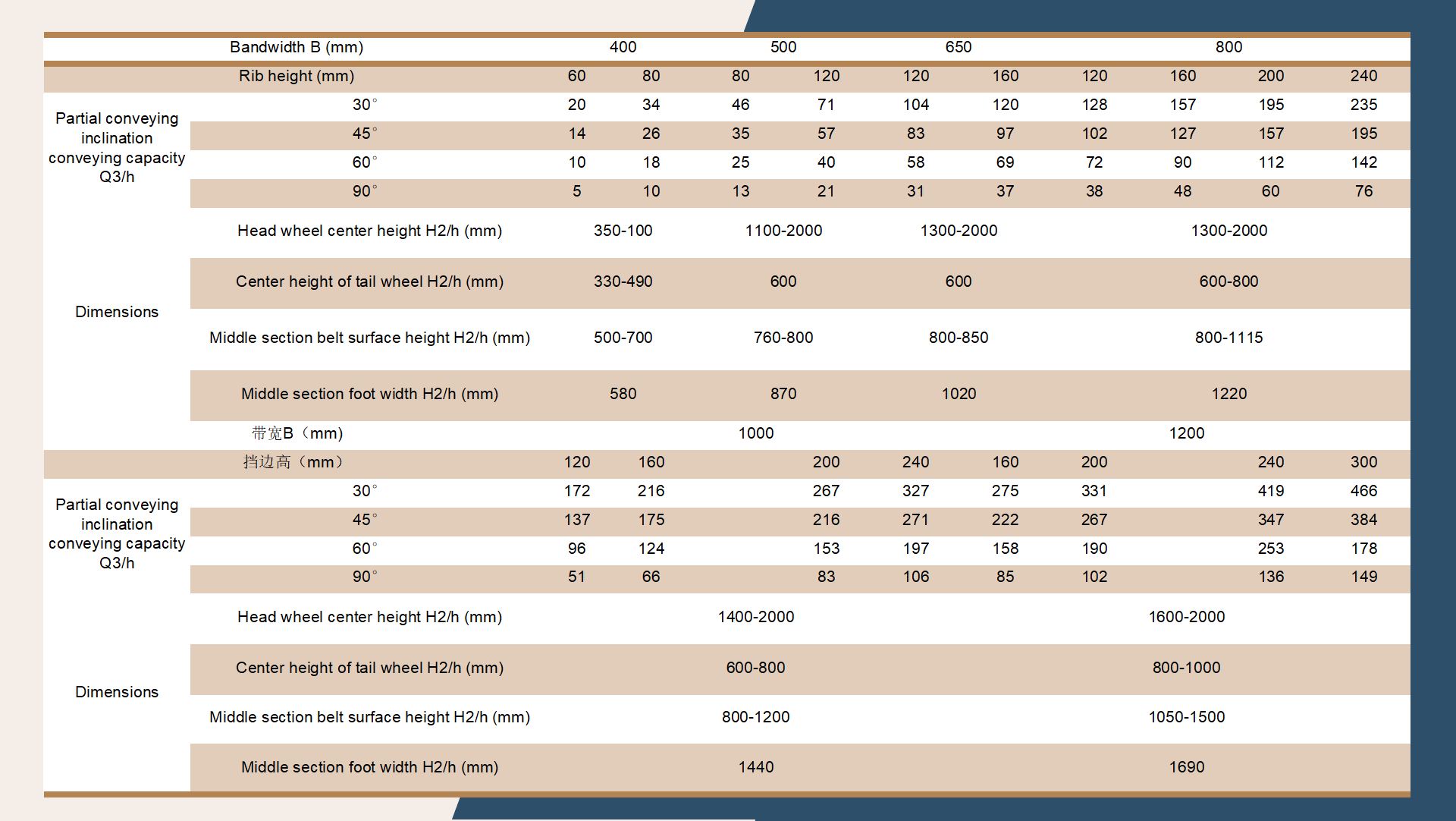

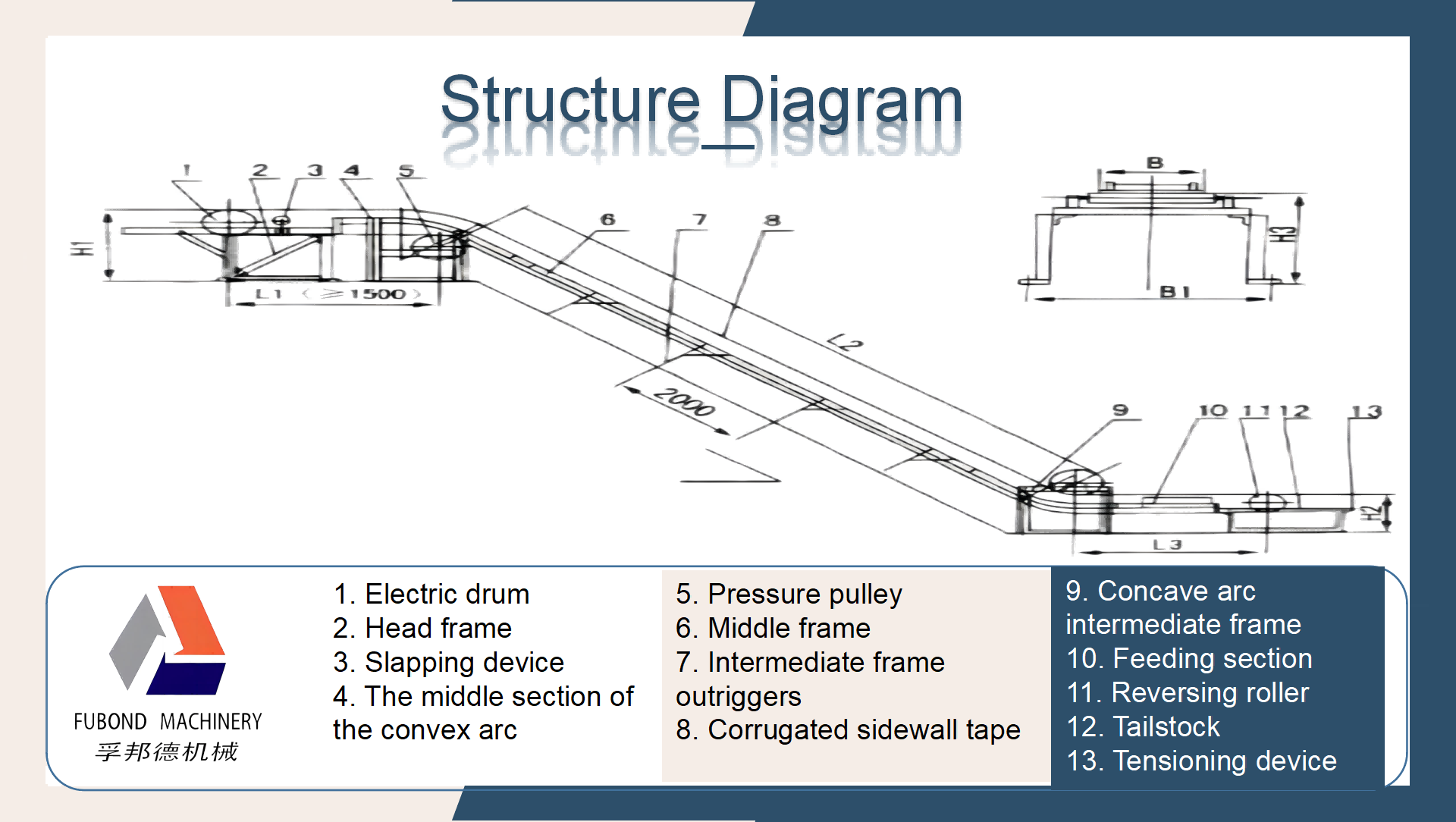

- The high-angle belt conveyor adopts a special corrugated rib conveyor belt: S-shaped or W-shaped rubber corrugated ribs of different heights are pasted on both sides of the ordinary conveyor belt (fabric core belt or steel wire core belt), and the cross partitions are spaced at certain intervals. Adhered to the base tape between the two side walls, it can effectively prevent materials from falling and spilling. - Since the high-angle belt conveyor is a conveyor belt that prevents material from overflowing, the inclination angle can reach more than 30 degrees without self-flow, and can even be transported vertically at 90 degrees, which completely solves the problem that ordinary and patterned belt conveyors cannot achieve. - Small footprint as bulk materials can be conveyed at wide angles. - Compared with ordinary lifting conveyors, it has greater conveying capacity (depending on the conveying angle and material type, etc.). - Ordinary lifting conveyors require pre-embedded steel plates as supports for the fixed tailstock before installation, while large-angle belt conveyors only need to be installed on site and can be put into use, saving users time and reducing labor intensity. - Because the large-angle belt conveyor is designed into three parts: the bottom horizontal section, the inclined section, and the head horizontal section. Therefore, the bottom or head horizontal section can be lengthened as required to complete the transportation work of ordinary horizontal fixed belt conveyors, realizing the multi-purpose function of one machine and making it easier to be used with other equipment. - The structure of the high-angle belt conveyor is basically the same as that of the general belt conveyor. Various components are standardized and easy to replace and maintain.

- It can be widely used in coal, grain, building materials, construction, metallurgy, electricity, chemical industry, light industry and other industries [3]. - It can transport various bulk materials with a bulk density of 0.5~2.5t/m3 in an environment range of -25~40℃. - The maximum conveying angle is 90°, and the maximum block size of the conveyed material is 550mm.